Kazhinji kutaura, maburi ane dhayamita ye0.1mm-1.0mm anonzi madiki maburi. Zvizhinji zvezvinhu zvinoshandiswa muzvikamu zvichagadzirwa zvakaoma-ku-muchina zvinhu, zvinosanganisira simende carbide, simbi isina tsvina uye mamwe mamorekuru anoumba zvinhu, saka akasiyana madiki madiki ekugadzira tekinoroji, nzira nemidziyo zvakagadziridzwa.

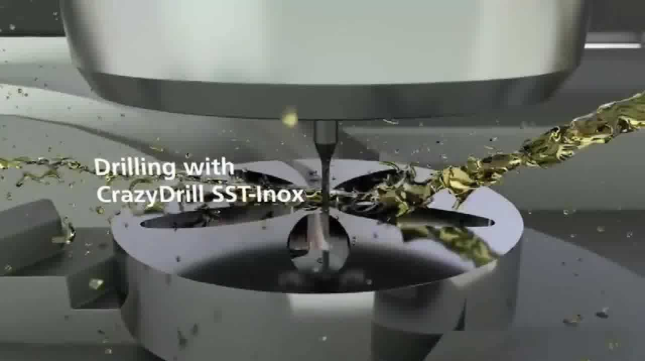

Pakati pazvo, nzira yekugadzira maburi maduku inzira yechinyakare yekugadzira ine nhoroondo refu, iyo inopedzwa nemidziyo kana drills, uye ikozvino ndiyo inonyanya kushandiswa.

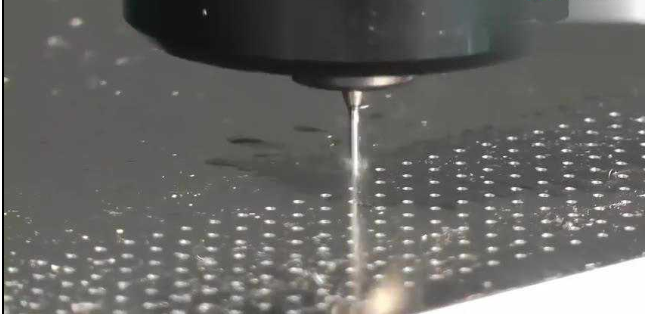

Mukushanda kwakasimba kwemakomba ataurwa pamusoro apa, kukurumidza kufamba kwechibooreso uye kumhanya kwechibhorani kunomhanya kwazvo, izvo zvinoda zvakanyanya zvinodiwa zvemuchina uye dhiri.

Kana mushandi achida kuita basa rakanaka, anofanira kutanga arodza maturusi ake. Paunenge uchichera maburi madiki nepakati machining, zvisinei kuti ndeipi mhando yemuchina wakanaka waunoshandisa, unofanirwa kutanga watanga, handiti?

Sei vanhu vachigadzira makomba madiki nekukurumidza uye zvakanaka?

Imwe yemapoinzi akakosha mugomba madiki machining ndeye chip control uye chip evacuation performance.

Chip control: Kuchekwa kwechibhorani kunoitwa mugomba rine nzvimbo yakamanikana, uye machipisi anofanirwa kuburitswa kuburikidza negororo redhiri, saka chimiro chechip chine simba guru pakucheka mashandiro echibooreso. Iwo machipisi akanaka anovharira kumucheto groove, anokanganisa kudhirowa, uye kuderedza hupenyu hwechibhorani; machipisi marefu anoputira chibooreso, chinotadzisa kushanda, chinoita kuti chibooreso chityoke kana kudzivirira mvura yekucheka kupinda mugomba.

Chip kubviswa kuita: Kana nzvimbo yekubvisa chip groove isina kukura zvakakwana, machipisi haagone kuburitswa zvakanaka, izvo zvinozotungamira mukutadza kudhirowa. Naizvozvo, zvinodikanwa kuwedzera nzvimbo ye chip flute kuti uwane barriers-yemahara chip kubviswa uye kuve nechokwadi chekugadzirisa kugadzikana.

Chimwe chinhu chakakosha mugomba diki machining ndeyekupfeka tekinoroji.

Coatings anowedzera kupfeka kwezvishandiso uye kuramba kupisa, nekudaro kuwedzera hupenyu hwematurusi.

Ikozvino, vagadziri vezvishandiso vazhinji vanoisa maburi emafuta ekutonhodza emukati pane chibatiso chekushandisa kubatsira kuwedzera kuyerera kweinotonhorera uye kuderedza kutonhora kwekutonhora. Kana iyo inotonhorera inoyerera yakakura, machipi anogona kuburitswa zvakanyanya uye yakagadzikana machining inogona kuwanikwa.

Ehe, kune dzimwe nzira dzakawanda kunze kwekugadzira maburi madiki: senge EDM, electron beam, laser, femtosecond laser, kemikari etching uye plasma yekucheka, nezvimwe.

Maererano nemakore akawanda echiitiko, chiyero chekugadzira fekitari chinogona kunzwisiswa nyore nyore nekuenda kuchimbudzi mufekitari yavo. Iyi nzira yakavimbika.

Muchiito chekubata nemafekitari, fekitori yega yega ichazivisa kuti yakavimbika sei mhando yezvigadzirwa zvayo uye kuti ma molds akanyatsoita sei ... Iwe haufanirwe kunzwisisa uye kuongorora kubva kuhunyanzvi hwekutanga, uye isu tichataura nezvazvo. muimba yekugezera!

Kuenda kune mamwe mafekitari, kunzwa kwekuenda kuchimbuzi kunofadza kwazvo. Mamiriro ezvinhu akajeka uye akachena, anoyevedza uye akatsvinda, chimbuzi chine bepa rechimbuzi, pane girazi pamberi pesingi, sanitizer yemaoko inowanikwa, uye pombi ine mvura inopisa uye inotonhora. Mukupesana, kuenda kuchimbuzi mune mamwe mafekitari kunotyisa uye hakutsananguriki. Iwe unoziva, paunouya kuchimbuzi, iwe uchapinda mune imwe nyika ine rima.

Nguva yekutumira: Oct-24-2022